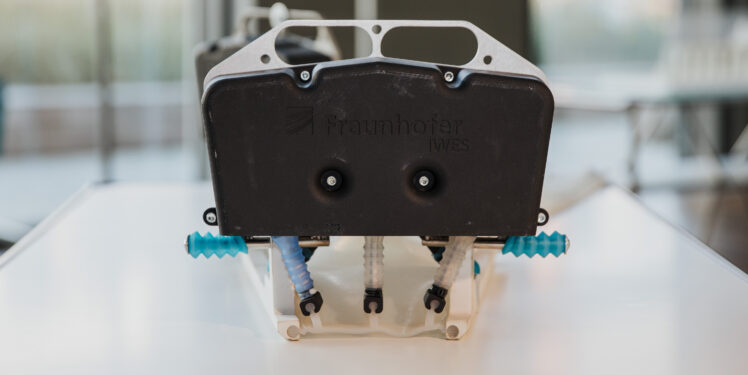

Fraunhofer IWES Wind Lidar Buoy achieves Stage-3 maturity level

The Fraunhofer IWES has presented a series of proofs of the quality and reliability of its FLS wind measurements. By achieving maturity level 3, the Fraunhofer IWES ZX wind lidar buoy joins the short list of stringently validated FLS types…