Blog post in three parts – The road to the blade bearing test

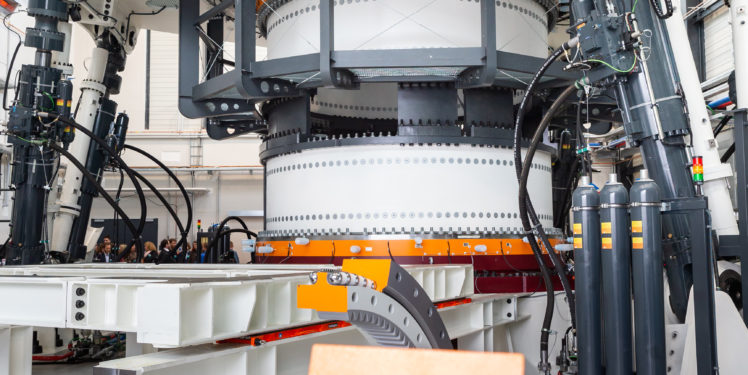

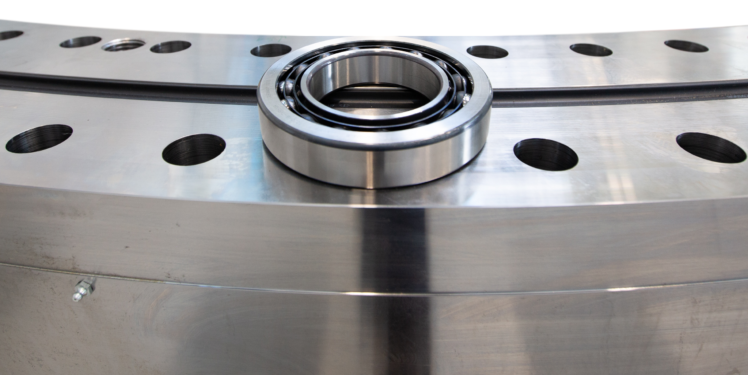

Part 3: Rapid testing of blade bearings – The first endurance run. In Part 1, I introduced the idea of an accelerated endurance run for blade bearings, which would consist of all wear-inducing cycles in direct succession. In Part 2,…