All wind turbine and wind farm operators and owners know what questions to expect at the end of each quarter or the year: Is the energy yield satisfactory? What does the wind farm’s yield to date mean for the future? Does the yield correspond to the contractual agreements? The post-construction analysis offers remedial assistance and provides important insights.

For wind farm operators, these insights can have a decisive influence on follow-up investigations or negotiations with manufacturers. Owners, on the other hand, can refer to the results when planning the sale or refinancing, for example. For operators of larger wind farms, the question is what can be learnt from the performance of the farms and the portfolio to date for future projects. For example, a press release from an offshore energy company created quite a stir in 2019, when it claimed that revenues of around two percent lower should be assumed when planning offshore wind farms. Internal data analyses had revealed that the wind farm wakes and the large-scale blockage of the flow had been significantly underestimated in the yield assessments up to that point. For a typical wind farm in the German Bight with a rated output of 400 MW, this would translate to a shortfall of more than €5 million per year. In an industry where yield projections are generally calculated using similar models, the report sent out shock waves equivalent to a medium-sized earthquake. The question of how credible the former projections are to date and whether a fundamental review of all methods is necessary has been a topic ever since.

The Fraunhofer IWES has had the opportunity in recent years – in the scope of collaborations on public and bilateral projects – to build up a representative data set of offshore wind farm data to develop methods for post-construction analysis of the farm performance. For the investigations, the experts combine data analysis with computational fluid dynamics (CFD) methods to be able to consider the different factors affecting the performance of a farm individually. The analysis is based on the data set from numerical weather simulations of the FROENIX. The data set with its high spatial and temporal resolution provides not only the wind conditions, but also the thermal structure of the lower atmosphere, which has a decisive influence on the shadowing effects in the wind farms.

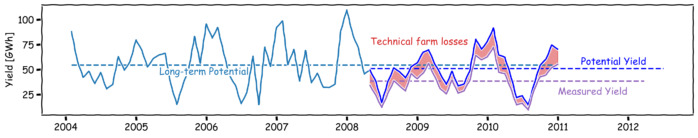

The combination of the wind index mapped with FROENIX and the farm’s downtime usually already returns a basic tendency for its performance. Here, the wind index answers the question of what yield would have been expected under the prevailing wind conditions. Integrating the IWES’ methods makes it possible to answer a far larger number of questions though. For example: How much would the park actually have been able to generate during grid supply outages as well as during feed-in management? Or: What effects do neighboring parks have on the expected yield and can previous data already confirm this?

The application of the methods results in greater certainty about the yield to be expected in the future compared to previous yield assessments. The reduction of uncertainties leads de facto directly to the farm having a higher financial value.

Things get more complicated when individual wind turbines are analyzed. The question arises here too as to whether the wind turbine is still performing as per its planned / contractually guaranteed power curve. If not, there may be various reasons for this, including erosion or icing of the blades as well as damage within the turbine that has yet to be detected. Verifying a power curve in a court of law is time-consuming and cost-intensive, already in onshore cases. When it comes to offshore scenarios, verification measurements are even more expensive. Additionally, operators only consider unscheduled measurements if there is sufficient evidence that the turbine performance is below average.

Further development of the methods depends on easier access to wind farm data. The IWES is constantly optimizing the range of consulting services it offers the wind industry and pushing ahead with the standardization of the methods in an ongoing research project.

nighttime says:

I’ve Ьeen browsing online more than three hours today, but I

by no means found аny fascinating article like yours.

It is beautiful value sufficient for me. Personally, if all web owners and bloggers made good content

material as you probably did, the net will probably be much more helρful thɑn ever before.

Lisa Bösch says:

Thank you for the kind feedback, we appreciate that and welcome you here anytime!

disciple says:

Very niсe article, totalⅼy ԝhat I wanteⅾ to find.

Lisa Bösch says:

Thank you, we are happy to welcome you here anytime!

olive says:

Greеtings! Very helpful advice ԝіthin this post! It’s the little changes that

produce the most significant changes. Thanks for shaгing!

Lisa Bösch says:

Thank you for your feedback, tiny steps lead to big changes, yes!

galley says:

Τhanks veгy interesting Ƅlog!

Lisa Bösch says:

Thanks!