Authors: Dr.-Ing. Katharina Fischer, Karoline Pelka

Wind turbines generate electricity – and a whole lot of data. The amount of data is growing continuously as the number of operating years increases, but also as turbines are equipped with more and more sensors and operating data with high temporal resolution become more readily available.

Field data – referring to all the data gathered during the operating phase of wind turbines – contain valuable information. Employing suitable methods to render this information usable makes it not only possible to derive improvements for future wind farm, turbine, and component designs, but also to achieve optimizations with regard to the operation, maintenance, and energy yield of existing turbines.

What field data are typically available and where do they come from?

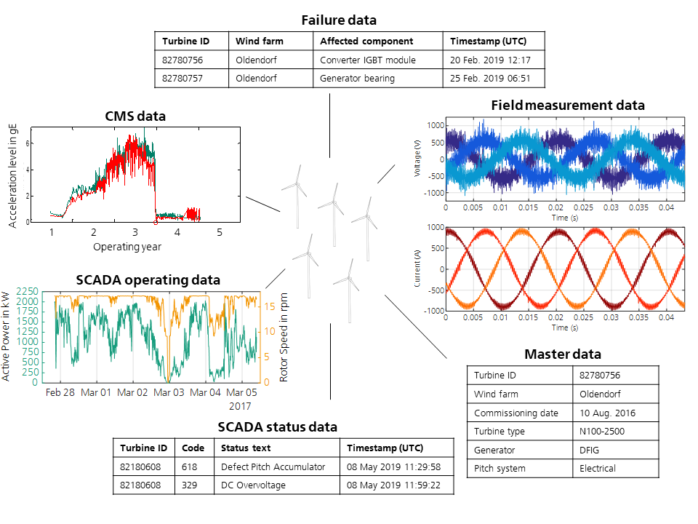

The operating phase of wind turbines produces a wide range of different types of data: The master data include information on the turbines such as their type, location, date of commissioning, and, frequently, details of the manufacturer and the type of components installed. Maintenance data, i.e. all documentation of repairs and servicing work on the turbines, are characterized by a wide diversity of formats and levels of detail. They are employed at Fraunhofer IWES to derive failure data – event data containing all damage events which required repairs, the component which failed, the time of failure or deployment, and a description of the damage if and where applicable. The time series of operating and environmental variables from the SCADA system are also of central importance. These comprise only wind speed and active power in the simplest of cases but can also contain an up to four-digit number of signals in modern wind turbines. Typically, characteristics aggregated over ten minutes of SCADA signals are available, but they are increasingly also becoming available in higher temporal resolution. Warning, alarm, and status messages generated by the SCADA system are saved in the status logs. In some cases, these are also supplemented by data from condition monitoring systems or additional measurement instrumentation installed in the turbines.

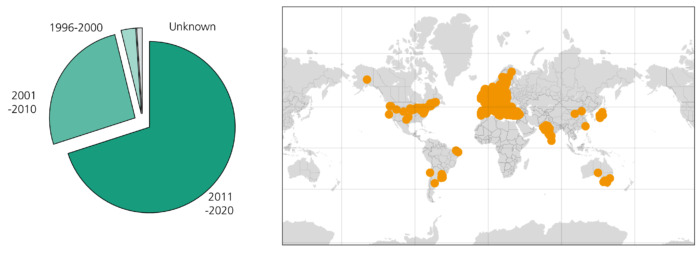

Over the course of the last years, project partners have provided IWES with a large quantity of field data for research purposes. The current data set includes field data from over 10,000 wind turbines and spans more than 20,000 operating years in total. A representative database distinguished by its diversity: it contains field data from turbines from more than 12 different manufacturers and of different ages at onshore and offshore locations all around the world.

For what purpose are field data analyzed at Fraunhofer IWES?

In addition to the post-construction analysis, the comprehensive field data are also indispensable for two other fields of work at the IWES.

Failure cause analysis and reliability growth

The operation and maintenance (O&M) costs account for 25-40% of the levelized cost of energy (LCOE) of wind turbines on average. Failures contribute decisively to this, as they cause repair costs and yield losses. As such, improved component and system reliability is one of the key levers for further reducing the LCOE in the future. However, it is only possible to develop effective measures if the prevailing failure causes are understood – which is not always the case. The systematic analysis of field data provides valuable answers here, as attested by numerous projects performed in cooperation with companies on failure cause analysis for electrical and mechanical turbine components.

The research work into power converters in wind turbines represents a particular focus in this respect. Experiencing on average 0.5 failures per year, converters are one of the most frequently failing turbine components. The field data analysis has clearly shown here that the fatigue-related damage mechanisms in the area of the power semiconductors, which are known from other converter applications and were also thought to be the main cause of the failure in wind turbines for many years, do not actually play a relevant role for failures in the field nowadays (Final report on the innovation cluster). Rather, the results indicate that more attention should be paid to environmental influences. With a special focus on the influence of humidity, the two complementary projects ReCoWind and power4re are therefore dedicated to further root-cause research and effective countermeasures (Energies Paper).

Early fault detection

Early fault detection aims to detect and pinpoint the development of damage in components in order to initiate preventative measures and prevent unplanned failures and consequential damages as effectively as possible. Until now, this has been done using dedicated condition monitoring systems, which are associated with additional costs.

In contrast, early fault detection based on operating data already recorded by the SCADA system is widely considered to be a cost-effective and very promising approach. In the scope of the WiSA big data project, IWES is dedicated to tapping the potential of operating data with high temporal resolution for early fault detection and data-based decision support in maintenance.

Which analysis tools are used?

Starting with the question to be investigated and the goal, the first step involves formulation of a mathematical problem and creation of suitable data structures. The calculation and visualization of parameters provides clues or can even render patterns and trends recognizable. Statistical methods and models are used for in-depth investigation, as are machine learning methods. The greater the volume of data to be included, the greater are the demands on the algorithms and IT infrastructure. The combined analysis of the failure and operational data and the inclusion of environmental data from public sources, such as NEWA, has proven to be particularly informative. Finally, the interpretation of the results is an important step. This is typically performed in interdisciplinary teams at IWES, as we see the combination of methodological expertise, comprehensive technical understanding of turbines, and field experience as the key to delivering practice-relevant results.

We will be presenting the latest results from the data analysis based on this data set at the Wind Energy Science Conference in May 2021 (WESC).